Rhenania - RHE 189c - Ugland Obo-One - 1:1250 - Waterline model - Original packed

incl. VAT., excl. Shipping costs

- Description

- Shipping

- Return

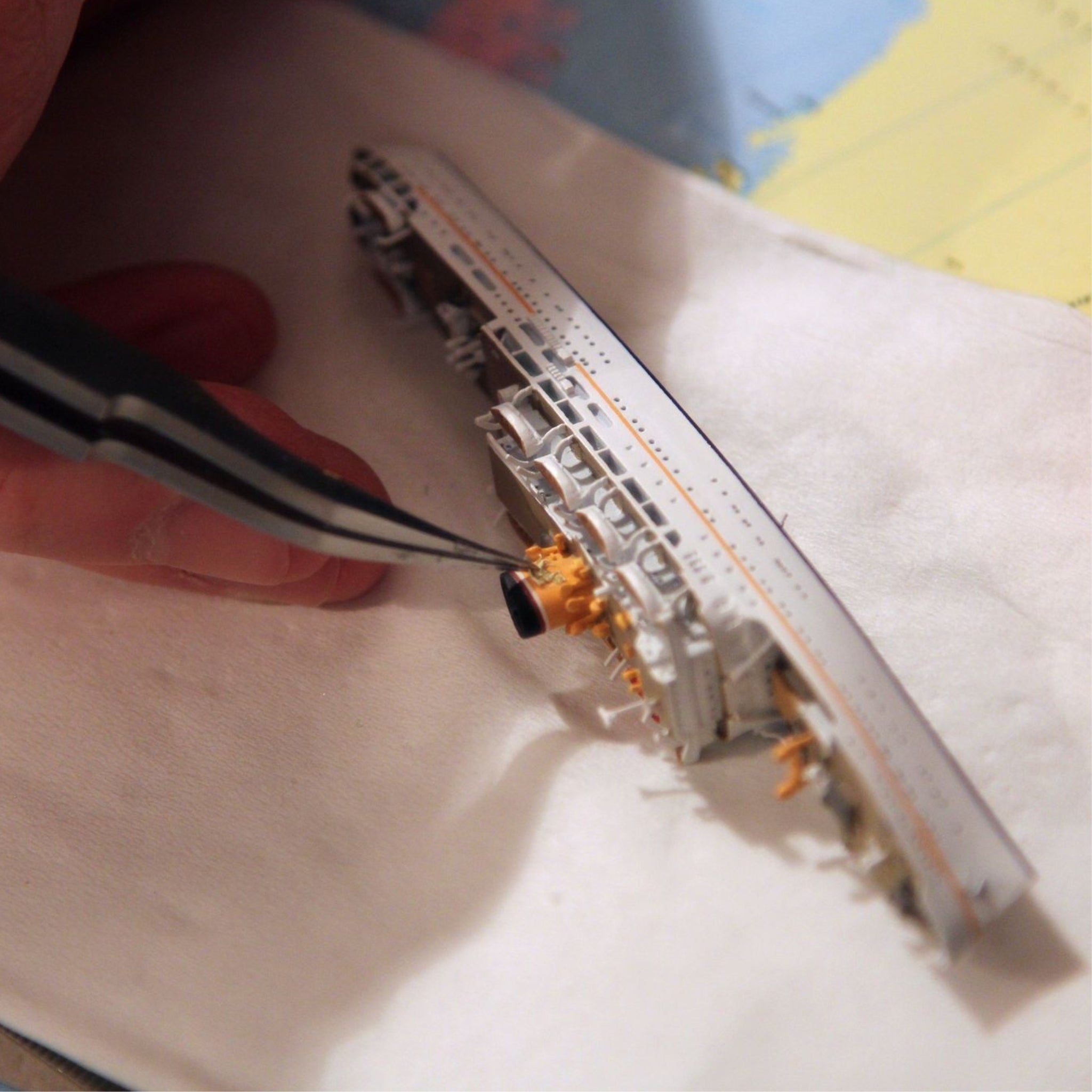

Ship model of the Ugland Obo-One in scale 1:1250 by Rhenania.

- Manufacturer: Rhenania

- Model number: RHE 189c

- Model type: Waterline model

- Scale: 1:1250

- Type of ship: Oil bulk ore carrier

- Ship name: Ugland Obo-One

- Shipping company: Ugland Managmt. Co.AS

- Condition: 1988

- Year of manufacture: 1983

- Material: Metal

- Model condition: Brand new

- Special feature: -

- Original packed: Yes

- Attention: 14+ no toy

- Delivery in Germany usually takes place within 2-3 working days.

- For more information about shipping costs, please follow the link .

- If you have any questions, please feel free to contact us at any time.

Please note that we cannot offer free return shipping and the costs are borne by the customer.

You can find more information here .

Complete the look:

Rhenania - RHE 189c - Ugland Obo-One - 1:1250 - Waterline model - Original packed

About Rhenania

The Rhenania models have been around since the 1970s. Over the years, many great models of merchant ships, icebreakers, work ships, freighters and bulkers have been created. From an early age, the son also watched his dad building models and so it didn't take long until he was building his own models. The Rhenania Junior series was born.

The production of the mold

First, a master model of a ship is created based on the general plan. This can be done either by hand or using 3D printing. The master model serves as a template and is then cast in silicone rubber. After the rubber has hardened, the master model is removed and the negative mold remains.

Production of the model ship

The negative mold is used as a mold to fill a hot metal alloy. The liquid metal fills all the fine angles of the shape, making all the details on the model visible later. After cooling, the cast model is removed from the mold and cleaned to prepare it for painting. The painting, painting and decal placement are all done by hand.